Cold Form Section

Cold form sections are thin steel sheets used in pre-engineered buildings (PEBs) to form structural shapes. The purpose of cold form sections is to distribute loads and provide lateral bracing from the building surface to the main framing and foundation.

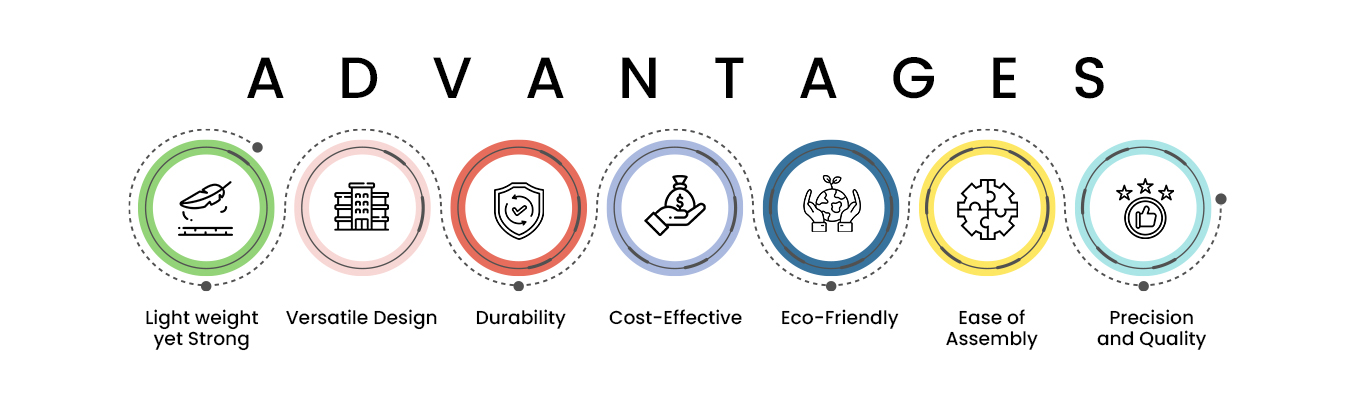

Cold form sections are lightweight, durable, and precision-engineered for strength and consistency in PEBs. Their corrosion resistance, adaptability, and eco-friendly nature make them ideal for modern, efficient construction.

KGS Building Systems brings together cold form structures and PEBs to offer reliable and customized solutions. We’re committed to building with quality and care.

FAQ’s

What are cold form sections in PEBs?

Cold form sections are thin steel sheets that are shaped at room temperature to create structural elements such as beams, columns, and braces in Pre-Engineered Buildings (PEBs).

Why are cold form sections important in PEBs?

Cold form sections are essential for providing strength and stability, distributing loads effectively, and offering lateral bracing from the building’s surface to the main framing and foundation.

How do cold form sections enhance the structural integrity of a PEB?

Cold form sections help distribute the weight and stresses of the building, improving its overall stability and performance, and ensuring safety during varying load conditions.

Are cold form sections more cost-effective than traditional steel framing?

Yes, cold form sections are more cost-effective because they are lighter, easier to transport, and faster to install, reducing both material and labor costs.

How do cold form sections contribute to the flexibility of PEB designs?

Cold form sections are versatile, enabling designers to create complex and customized structural shapes that align with specific building requirements and architectural styles.

Are cold form sections durable?

Yes, cold form sections are made from high-quality steel that is resistant to corrosion, ensuring long-lasting performance and minimal maintenance in PEBs.

What are the key advantages of using cold form sections over hot-rolled steel in PEBs?

Cold form sections are lighter, more efficient in material usage, and easier to fabricate, making them a more practical and cost-effective choice for certain PEB applications.

How do cold form sections help in load distribution in PEBs?

Cold form sections are designed to efficiently distribute vertical and lateral loads across the structure, ensuring the building can withstand forces such as wind, seismic activity, and live loads.

Can cold form sections be used in all parts of a PEB?

Yes, cold form sections are used in various parts of PEBs, including the framing, walls, and roof, where their strength, light weight, and ease of installation are highly beneficial.

What is the lifespan of cold form sections in a PEB?

With proper design and maintenance, cold form sections in PEBs can last for decades, offering a durable and long-term solution for structural needs.

Address

B-2-1C 1D, Bulandshaher Road,

Industrial Area, Ghaziabad - 201001

Phone

+91- 92663 00277

0120-3512478

0120-3512478

info@kgsbuilds.com

About Us

Specializing in pre-engineered steel buildings, the professionals at KGS Building Systems Pvt. Ltd. provide over 17 years of customer service experience. By offering design consulting and the engineering of Read More..

Quick Links

Contact Us

Privacy Policy

Terms & Condition